The Two-Stroke Engine Cycle: Part Three

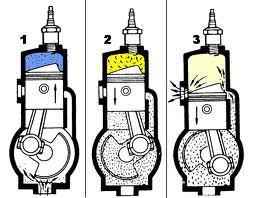

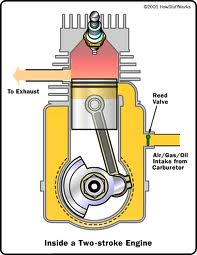

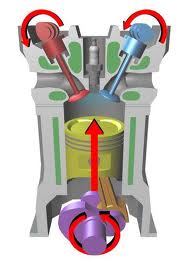

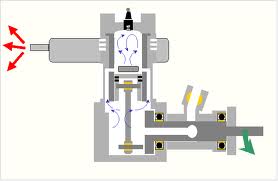

After reading the two previous blog posts, you’ve probably realized that the piston is the star of the show in the two-stroke engine. It serves three main purposes during the engine cycle. First, it acts as the combustion chamber, pressurizing the mixture of air, gas and Yamaha oil and capturing the power created by the subsequent ignition of that fuel. In addition, the piston also serves as the crankcase when it facilitates the flow of air and fuel into the system via the reed valve.

After reading the two previous blog posts, you’ve probably realized that the piston is the star of the show in the two-stroke engine. It serves three main purposes during the engine cycle. First, it acts as the combustion chamber, pressurizing the mixture of air, gas and Yamaha oil and capturing the power created by the subsequent ignition of that fuel. In addition, the piston also serves as the crankcase when it facilitates the flow of air and fuel into the system via the reed valve.

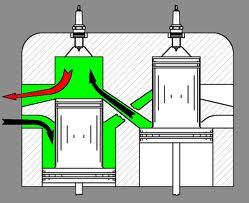

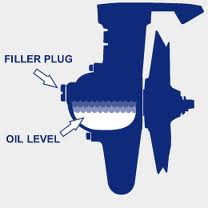

While all of this is occurring, the piston is also taking the place of the valves as it covers the intake and exhaust ports in the cylinder walls. The multifaceted nature of the piston is what allows for the two-stroke engine’s lightweight and powerful construction. Remember that the piston is under constant tension and doesn’t have a direct source of lubrication, so be sure to be diligent when you’re mixing your gas and oil.