Pre-Ride Snowmobile Checks

Living in the Pacific Northwest, I have been disappointed with the snow this season—to put it lightly. Usually I take my snowmobiles out several times a week, but for most of the season it hasn’t even been worth my time. This weekend I’m heading out to my buddy’s cabin, and there is sure to be some prime powder. To that end, I am going to do some basic maintenance and checks on my snowmobiles, which have been largely neglected this season.

There are a few checks that I check before every ride, including the fuel and level of Yamalube oil. I also make sure to check the engine coolant and brake fluid, just to be sure that they aren’t running too low. Remember to always inspect the engine coolant when the machine is cold to get an accurate reading. Tomorrow I will go over some other basic maintenance points that should always be checked before heading out.

Yesterday we went over the main idle adjustments, and today we will delve in deeper to how to fine tune the carburetor on your ATV. Once the idle is set, it is time to make minor adjustments to the various idle positions. For the off idle to ¼ throttle, the slow jet and slow air jet are the most effective means of getting the results that you want; use a larger slow jet and smaller slow sir jet for a richer mixture, and vice-versa.

Yesterday we went over the main idle adjustments, and today we will delve in deeper to how to fine tune the carburetor on your ATV. Once the idle is set, it is time to make minor adjustments to the various idle positions. For the off idle to ¼ throttle, the slow jet and slow air jet are the most effective means of getting the results that you want; use a larger slow jet and smaller slow sir jet for a richer mixture, and vice-versa. The carburetor is one of the most vital components of any two-stroke engine, as it works to blend the air, fuel, and

The carburetor is one of the most vital components of any two-stroke engine, as it works to blend the air, fuel, and  Aside from your house or car, a boat is probably one of the biggest purchases that you will ever make. With that in mind, it is important to do some research before dropping thousands on a watercraft. One of the most important things to consider is whether you want an inboard or outboard motor.

Aside from your house or car, a boat is probably one of the biggest purchases that you will ever make. With that in mind, it is important to do some research before dropping thousands on a watercraft. One of the most important things to consider is whether you want an inboard or outboard motor. Now that we have overviewed the inner workings of a two-stroke engine, the advantages should be ascertainable. The consolidation of the stroke cycle allows for a more rudimentary and lightweight design, which also produces more power. This combination makes two-stroke engines ideal for various handheld equipment and small vehicles. With these obvious advantages, some may be wondering why two-stroke engines aren’t used in cars and other large vehicles.

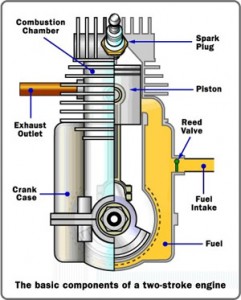

Now that we have overviewed the inner workings of a two-stroke engine, the advantages should be ascertainable. The consolidation of the stroke cycle allows for a more rudimentary and lightweight design, which also produces more power. This combination makes two-stroke engines ideal for various handheld equipment and small vehicles. With these obvious advantages, some may be wondering why two-stroke engines aren’t used in cars and other large vehicles. Yesterday we overviewed the main process that takes place in the cycle of a two-stroke engine. Now we are going to breakdown this process a little further to better understand what is occurring in this process. When the piston is working in its cycle, the crankshaft will give the piston momentum so that it can return to the spark plug for the compression stroke. During this process the piston compresses the mixture of

Yesterday we overviewed the main process that takes place in the cycle of a two-stroke engine. Now we are going to breakdown this process a little further to better understand what is occurring in this process. When the piston is working in its cycle, the crankshaft will give the piston momentum so that it can return to the spark plug for the compression stroke. During this process the piston compresses the mixture of  Yesterday we overviewed some of the basics differences between four and two-stroke motors. Today we will go over some of the mechanical operations of the engine. A two-stroke engine is essentially a simplified version of the four-stroke, and this means that the cycle is more economical and many of the operations are consolidated. As we said previously, one of the biggest differences is that the spark plug fires once every revolution, as opposed to every other revolution.

Yesterday we overviewed some of the basics differences between four and two-stroke motors. Today we will go over some of the mechanical operations of the engine. A two-stroke engine is essentially a simplified version of the four-stroke, and this means that the cycle is more economical and many of the operations are consolidated. As we said previously, one of the biggest differences is that the spark plug fires once every revolution, as opposed to every other revolution.